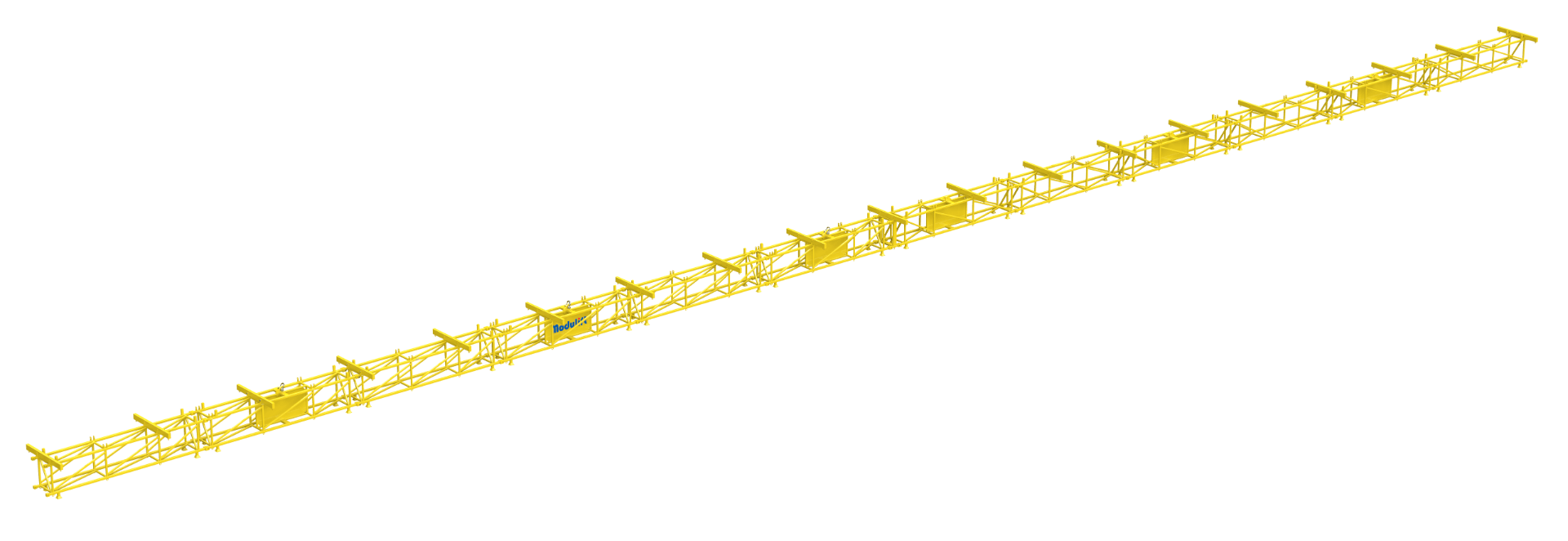

Lattice Spreader Beams

Multi-Point Lattice Spreader

Lattice Spreader Beams are ideal for long, light loads where a Spreader Beam is deemed too short for the lift. The Lattice Spreader Beam has been designed to be lightweight so as to allow for easy transportation and storage as well as being a cost-effective piece of Lifting Equipment.

The Modulift ‘Standard’ Modular Lattice Spreader Beam has a capacity of 3 and 5t and a maximum span of 42m at reduced capacities. Lattice Spreader Beams are ideal for long, light loads that require multiple support points along its length, for example; commercial roof sheet bundles, or twin wall drainage pipe require support along their length to support them whilst being lifted.

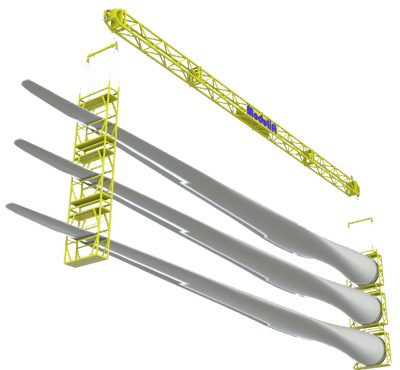

2-Point Lattice Spreader Beams

In addition to the standard ‘multipoint’ lattice, Modulift can design and manufacture custom, higher capacity multi point and two point lattice frame systems. Over the years these kind of systems have proved a popular choice in the wind energy blade lifting arena.

Why Trust Modulift for your Lattice Beams?

Modulift have been manufacturing high-grade lifting equipment for over two decades. We have supplied our beams to projects worldwide, always ensuring our products meet the outstanding quality we are known for.

After discussing your project’s requirements with you, we will use our expertise to design and supply a lifting beam that performs exactly as you need it to. We will offer you our expert guidance all the way, so you can be sure you’re getting the absolute most value out of your investment.

Wondering how our beams have been used in the past? Read through our case studies!

Lattice Beam FAQs

Key features of a Lattice beam may include:

- Longitudinal Main Beam: Lattice beams typically consist of a horizontal beam running along the longitudinal direction of the lattice with attachment points on top for connecting lifting slings or hooks.

- Transversal Cross Beams: The beam may have cross beams to accommodate the width of the roof sheets, ensuring stable lifting and distribution of the load.

- Adjustable Attachment Points: Lattice beams usually have mounted adjustable attachment points or multiple lifting positions to accommodate various roof sheet sizes and configurations.

- Safety Measures: Lattice beams often incorporate safety features such as locking mechanisms or safety pins to secure the attachment points and prevent accidental release of the load during lifting.

- Durability: These lifting beams are typically constructed from sturdy materials such as steel to withstand the weight of lifting heavy roofing materials.

- Ease of Use: Lattice beams are designed for ease of use, with simple attachment and detachment mechanisms to streamline the lifting process.

Lattice beams are essential tools in the roofing industry, facilitating efficient and safe installation of roofing materials while reducing the risk of injuries and damage to property. They are commonly used by roofing contractors, construction companies, and building maintenance crews to handle a wide range of roofing materials with precision and reliability.

A lattice spreader beam is a modular lifting frame designed for handling long, lightweight, or delicate loads that require multiple pick points. It’s ideal when traditional spreader beams are too short or heavy for the application.

Lattice beams offer several advantages that make them indispensable tools in the construction industry:

- Enhanced Safety: Lattice beams provide a secure and stable method for lifting and manoeuvring heavy roofing materials, reducing the risk of accidents, injuries, and property damage during installation.

- Efficiency: By streamlining the lifting process, Lattice beams help improve efficiency and productivity on the job site, allowing roofing projects to be completed more quickly and with fewer labour resources.

- Damage Prevention: The even distribution of weight provided by Lattice beams helps prevent damage to delicate roofing materials, such as metal sheets or composite panels, during handling and installation.

- Versatility: Lattice beams are designed to accommodate a wide range of roofing materials, sizes, and configurations, making them suitable for various types of roofing projects, from residential homes to commercial buildings.

- Ease of Use: With simple attachment and detachment mechanisms, Lattice beams are easy to set up and operate, reducing the time and effort required to lift and position roofing materials.

- Durability: Constructed from steel, Lattice beams are built to withstand the rigors of daily use in challenging construction environments, ensuring long-term reliability and performance.

Overall, Lattice beams offer a safe, efficient, and cost-effective solution for handling and installing roofing materials, making them an essential tool for roofing contractors and construction professionals.

The safe working load (SWL) for Lattice beams can vary depending on several factors, including the design and construction of the lifting beam, the materials being lifted, and the specific application. It is crucial to consult the User Instructions provided to determine its safe working load capacity.

Generally, Lattice beams are designed and rated to safely lift and handle a certain maximum weight or load. This safe working load should not be exceeded during lifting operations to ensure safety and prevent equipment damage or failure.

Factors that can affect the safe working load of Lattice beams include:

- Material Strength: The strength and load-bearing capacity of the materials used in the construction of the lifting beam, such as steel or aluminium.

- Beam Design: The design and structural integrity of the lifting beam, including the configuration of attachment points and lifting spreaders.

- Load Distribution: How the load is distributed across the lifting beam and attachment points, including the use of appropriate lifting slings or hooks.

- Environmental Conditions: The environmental conditions and operating environment, such as wind, temperature, and terrain, can impact the safe working load of the lifting beam.

It is essential to conduct a thorough risk assessment and ensure that the safe working load of the Lattice beam is not exceeded to maintain a safe working environment and prevent accidents or injuries. If in doubt, contact our in-house technical engineering team.

Modulift lattice spreader frames can be configured for spans up to 42 metres and have a capacity of 3 and 5 tonnes, depending on the load and lifting configuration. Capacities vary by setup but are designed to safely support evenly distributed loads across multiple lift points.

The safe working load (SWL) of a Lattice beam is typically based on engineering calculations, testing, and compliance with safety standards. As an end user, it’s crucial to rely on the User Instructions and not attempt to calculate the SWL independently, as it involves complex engineering considerations.

However, it’s helpful to understand some of the factors that manufacturers take into account when determining the SWL of a lattice beam:

- Material Strength: The material from which the Lattice beam is made plays a significant role. Different materials have varying strengths, and the manufacturer considers the minimum yield strength of the material to establish load-bearing capacity.

- Design Factors: The design of the Lattice beam, including its shape, size, and construction, influences its load-bearing capacity. Engineering principles are applied to ensure that the beam can safely distribute loads without failure.

- Geometry and Configuration: The geometry of the Lattice beam and the arrangement of attachment points are critical. The manufacturer considers how these factors affect the stress and loading on the beam.

- Welding and Connections: The quality of welding and connections is essential for the overall strength of the Lattice beam.

- Testing and Certification: Lattice beams typically undergo rigorous testing to verify their load-bearing capacity. Certification processes may involve static load tests, dynamic load tests, and other assessments to ensure the beam’s reliability.

- Factor of Safety: We apply a factor of safety to the calculated load-bearing capacity to provide an additional margin of safety. This factor accounts for uncertainties in the load, variations in material properties, and other potential factors that could affect the beam’s performance.

As an end user, it’s crucial to:

- Refer to User Instructions: Always consult the User Instructions provided.

- Follow Guidelines and Standards: Adhere to industry standards and guidelines for the use of lifting equipment. Compliance with established safety standards helps ensure that the roof sheet lifting beam is used safely and within its intended parameters.

- Regular Inspections: Periodically inspect the Lattice beam for signs of wear, damage, or other issues. Any concerns about the integrity of the lifting beam should be addressed promptly, and the equipment should be taken out of service if necessary.

If there are uncertainties or if modifications to the Lattice beam are needed, consult with the our in-house technical engineering team. Attempting to calculate or modify the safe working load without proper knowledge and expertise can compromise safety.

The modular design allows custom configurations to match specific loads, lifting environments, or rigging arrangements.

The lattice frame is modular and designed for efficient transport in standard shipping containers and lorries. On site assembly is straightforward using standard tools, and the pinned design eliminates the need for welding or specialist fabrication.

All Modulift lattice spreaders are designed in accordance with the international lifting equipment standard BS EN 13155.

These frames are widely used in offshore, wind, construction, and heavy manufacturing sectors – especially where loads are long, delicate, or have multiple pick-up points such as roof sheets, wind turbine blades, masts, or modular building sections.

Modulift’s sales and engineering teams can help determine the right lifting solution for your project. The suitability of a lattice beam depends on several factors, including load length and weight, available headroom, and any rigging constraints.

Routine visual inspections should be conducted before and after use for signs of damage, deformation, or corrosion. 6-monthly inspections by a competent person are recommended, in line with LOLER and other relevant regulations.