Spreader Beams and Frames: A Lifting Equipment Guide

- Types of Spreader Beams Explained

- Choosing Between Fixed and Modular Spreader Frames

- Frequently Asked Questions

An overview of the different types of spreader beams and frames, along with their specific uses, advantages and disadvantages.

Spreader beams and spreader frames play a crucial role in safe and efficient lifting operations across industries such as construction, shipping, and heavy engineering. This guide explores the different types available, their unique features, and their best-use scenarios to help you choose the right equipment for your needs.

There are several types of spreader beams and frames used in lifting operations. Each type is designed for specific load types, lifting conditions, and safety requirements. Below is a breakdown of different types of spreader beams and frames, including their features and applications:

Types of spreader beams explained

Spreader beams are designed to protect the load by keeping slings at a fixed distance apart. They can be simple or more complex depending on the application. The guide below will help in choosing the right spreader beam for your lift.

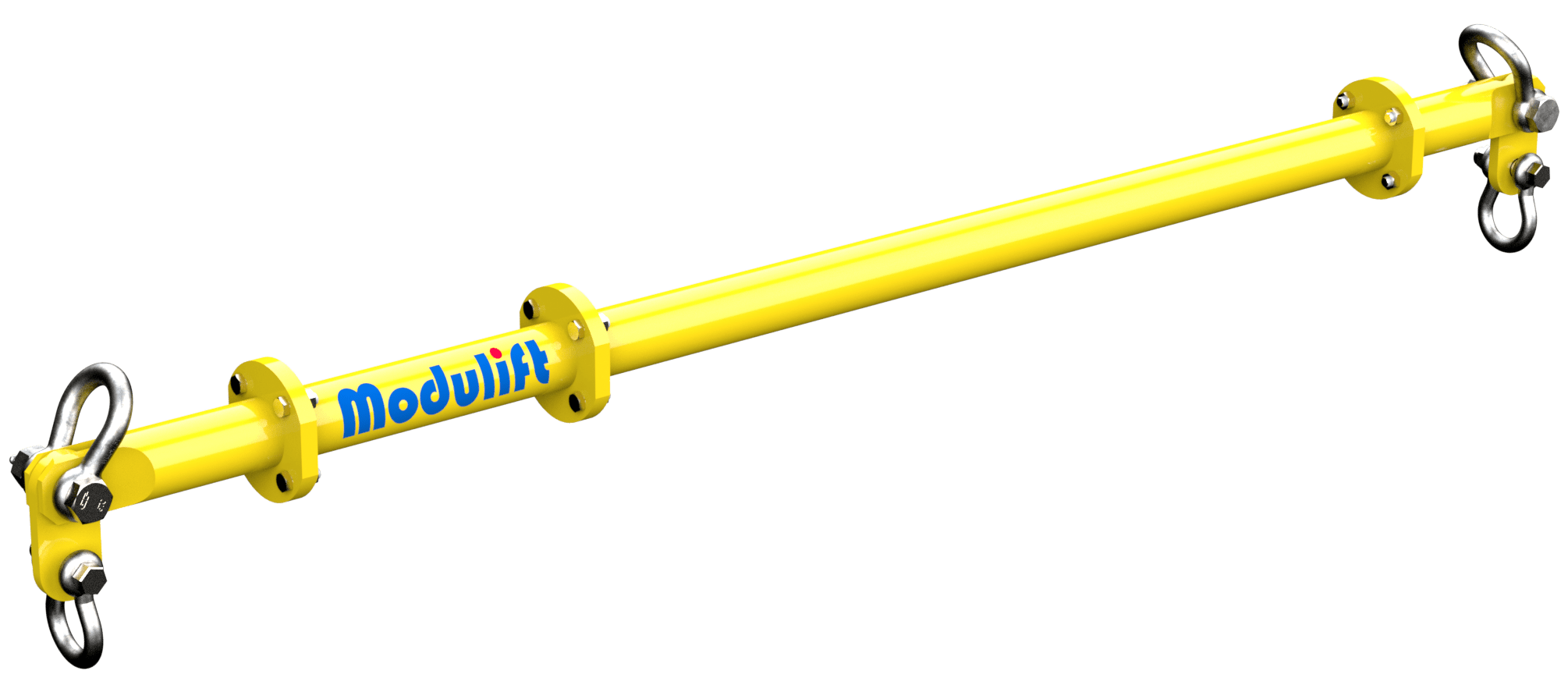

Modular Spreader Beam

Modular spreader beams such as the MOD are built from multiple interchangeable components that can be reconfigured for different lifting tasks. They are versatile and often used in construction, shipyards, oil and gas, renewables and the transport & logistics industry for lifting a wide range of loads.

- Advantages: Reduces the need for multiple beams, cost-effective, easy to transport and store, very lightweight in comparison to other types of lifting and spreader beams.

- Disadvantages: Can be expensive for one-off lifts.

- Examples of Use: Ideal for lifting objects of varying sizes, such as large machinery, prefabricated structures, or containers.

Fixed Spreader Beam

Rigid in design, a fixed spreader beam is a non-adjustable beam with fixed lifting points. It is suitable for lifting tasks with constant load dimensions.

- Advantages: Simple and robust design, often used for repetitive lifting tasks.

- Disadvantages: Not suitable for multiple applications, not adaptable, difficult to transport and store.

- Example: Lifting a specific size of steel pipes or precast concrete elements.

Adjustable Spreader Beam

The beam’s lifting points can be adjusted to accommodate different load sizes. Adjustable spreader beams give flexibility for lifting various load sizes and shapes.

- Advantages: They provide flexibility to handle different tasks with the same beam, reducing the need for multiple lifting devices.

- Disadvantages: They tend to be heavier, capacities tend to be lower. Also, the main structure and / or longest modular sections make them more difficult to transport and store.

- Example: Adjustable spreader beams are often used in construction sites where load dimensions frequently change.

Telescopic Spreader Beam

Adjustable in length through a telescoping mechanism, allowing it to extend or retract to fit different loads. Telescopic spreader beams are useful when load dimensions are unpredictable, or they are being used in tight spaces.

- Advantages: Quick and easy to adjust.

- Disadvantages: Used at lower capacities, difficult to adjust at higher capacities, tend to be heavy, can still be long when not in an extended position.

- Example: They are often used for lifting long pipes or beams with varying lengths.

Choosing between fixed and modular spreader frames

Spreader frames distribute loads over multiple points to lift large or oddly shaped objects safely. Unlike spreader beams, our CMOD spreader frames are typically used for more complex, multi-point lifting tasks.

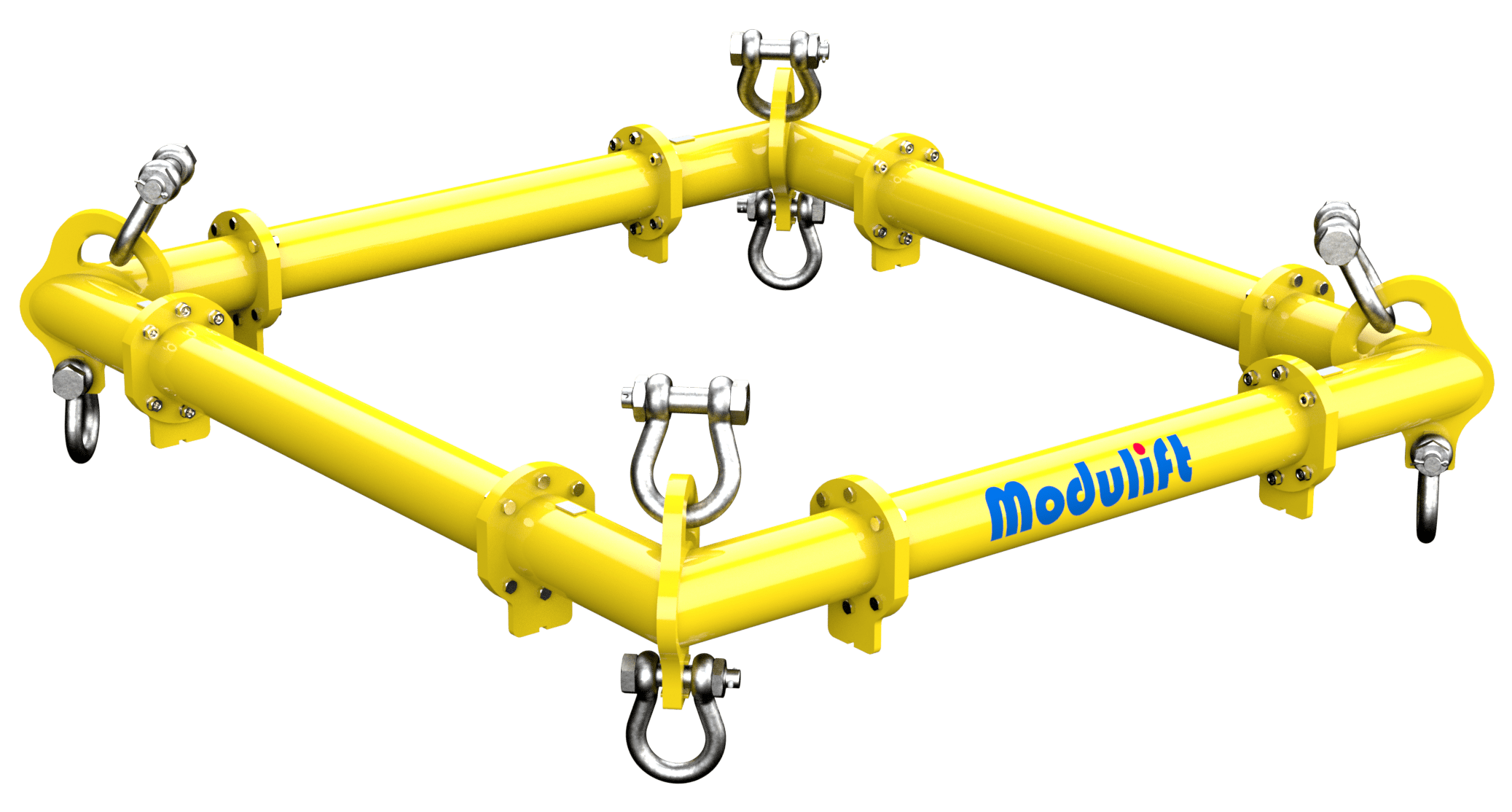

Modular Spreader Frame

Modular spreader frames such as the CMOD and TriMOD are made up of interchangeable components that can be configured in different shapes and sizes, depending on the load. Designed for either a 3, 4, 6 or 8 point lift. They provide flexibility for lifting various types of loads by adjusting the frame’s size and layout.

- Advantages: Adaptability to different lifting operations, reconfigurable for various projects, interchangeable components enabling struts to be utilised from spreader beams, and additional components such as corner units and T-pieces can be added for multiple point lifts.

- Disadvantages: Can be expensive for one off lifts.

- Example: Used for lifting complex, multi-point loads at low headroom, such as: HVAC units, machinery, or large construction modules.

Fixed Spreader Frame

A fixed spreader frame is a rigid frame with fixed dimensions and lifting points. These are perfect for lifting tasks that involve consistent load shapes and sizes.

- Advantages: Easy to set up and use for repetitive lifting operations.

- Disadvantages: Not suitable for multiple applications, not adaptable, and also they are difficult to transport and store.

- Example: Ideal for lifting pre-assembled panels or containers of a standard size at low headroom.

>Frequently Asked Questions:

What’s the difference between spreader beams and lifting beams?

Spreader beams and lifting beams are both used to lift heavy loads, but the two are used in very different applications. The main difference between a spreader beam and a lifting beam is the force being applied to the beam: a lifting beam puts a bending stress on the beam, whereas a spreader beam puts a compression stress on the beam.

Can spreader beams be used in extreme weather conditions?

Yes they can, but the use of Modulift spreader beams must be in accordance with the procedures laid down in ‘Lifting Operations and Lifting Equipment Regulations’ 1998 (LOLER). MOD spreader beams can be used in temperatures ranging from -20 degrees to +40 degrees.

What types of slings can be used with spreader beams and frames?

Textile slings, wire rope slings with soft eyes and chain slings with small end fittings can all be used. If thimble eyes are used with wire rope slings, the sling angle must be 30 degrees or less. Other types exist but not all are suitable due to the end fitting size, particularly larger capacity chain hooks and thimble eyes.

Need help choosing the right spreader beam or frame? Call 01202 621 511 or email [email protected] for a quote. Download the Modulift Brochure to view Load v Span Charts. For worldwide delivery, find your nearest Modulift Distributor.